Anhydrous Ammonia Knife Monitor

The Hiniker Nitro-Lert anhydrous ammonia knife monitor system alerts operators to individual blocked manifold outlets, lines or knives. In-line sensors for each outlet monitor for flow variations and alert the operator to potential problems.

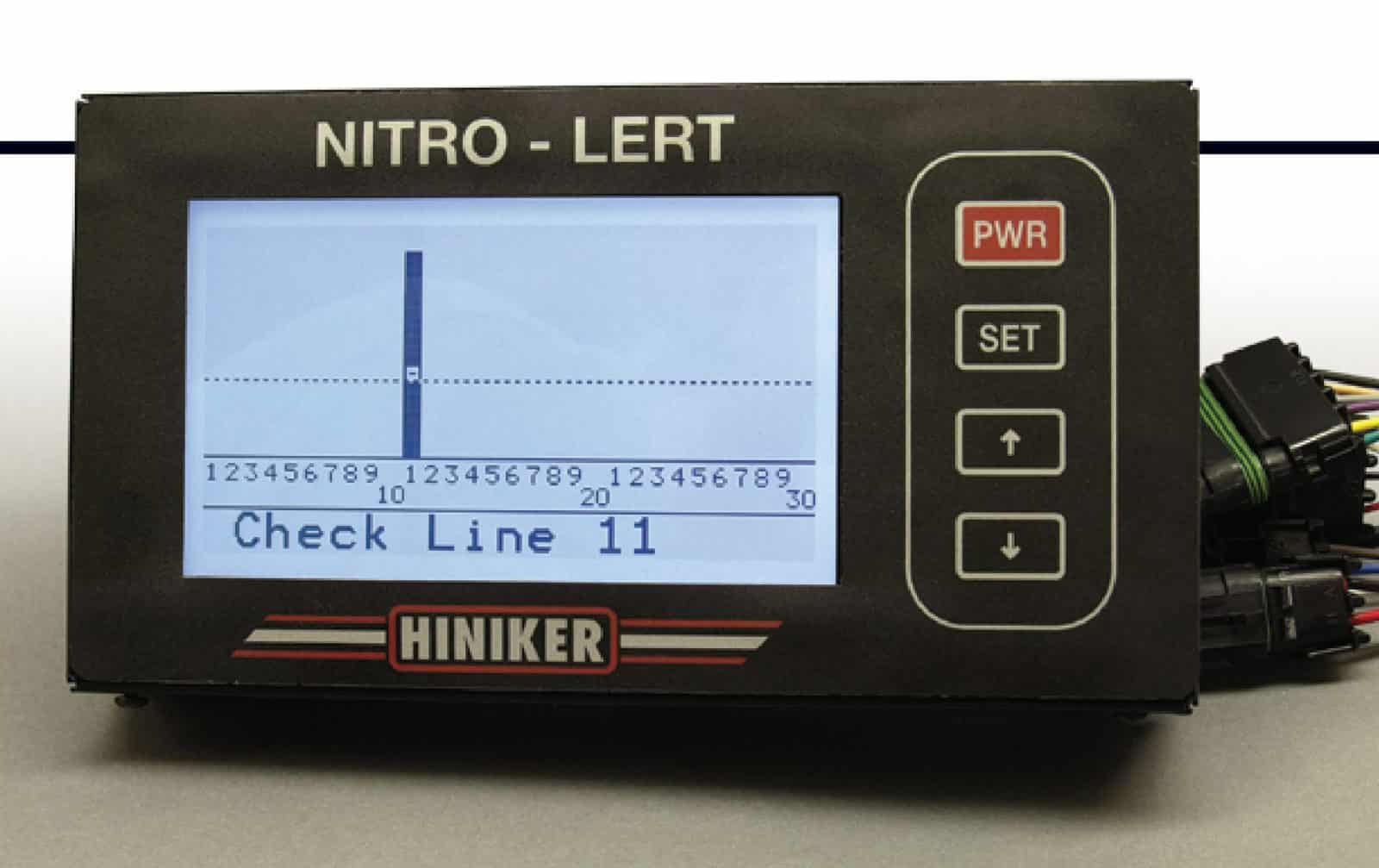

A user-friendly in-cab monitor panel displays the status of up to 80 individual outlets. If a malfunction is detected, an audible alarm is sounded and the display indicates which line is blocked. The operator then has the choice of correcting or ignoring the problem.

The Nitro-Lert system works independently of any other monitor or rate control systems that may be installed. Factory-issued installation guidelines should be followed to assure optimum performance with your particular set-up.

Typical problems the Nitro-Lert detects:

- Nitro-Lert detects plugged knives that occur when the operator turns off the flow to one section of the applicator. When the section is turned back on, the operator can see if one of the knives is plugged with dirt, blocking flow and triggering a Nitro-Lert notification.

- Broken knives. Nitro-Lert detects a variation in flow through the broken knives and alerts the operator of the problem.

- Nitro-Lert detects partial blockage caused by welding slag that could be left in the knife tubes during the manufacturing process.

With a Nitro-Lert system you’ll detect problems as they occur, while they can be corrected!

NITRO-LERT ALERTS THE OPERATOR:

- When a knife is plugged or partially blocked.

- When a blown or loose line causes excessive flow to a knife

- When a manifold outlet is plugged or partially blocked.

INDEPENDENT FREE-STANDING SYSTEM

- In-cab bar graph display constantly monitors each manifold outlet.

- Audible alarm alerts operator of malfunction.

- User-friendly interface.

With a Hiniker Nitro-Lert System, plugged or partially blocked knife outlets can be easily detected before it’s too late as shown in photo.

Sensitive enough to help calibrate the system and point out outliers in the system like short or kinked hoses.

Frequently Asked Questions:

- What does the NitroLert do?

The NitroLert system is a temperature sensor system that takes the average temperature of the sensors and compares each sensor to that average. When a sensor warms or cools by more than the tolerance that the Alarm Point allows, the NitroLert alerts the operator stating which sensor, or knife, is failing.

- What does the + and – mean on the bar graph?

The sensors operate on temperature, so + is warmer and – is colder. In most cases + means a decreased flow and could be a partial or complete blockage. The – symbol can mean increased flow, like a shorter hose length or a hose pulled off a barb. You can also get a – symbol when there is a partial blockage right before the sensor, at a hose barb or orifice for example.

- How does the NitroLert work?

Each sensor is located a fixed distance from the distributor, which allows the sensors to monitor the temperature when the anhydrous reacts to the pressure drop. This reaction can cause the temperature to vary greatly depending on the flow and pressure. If all the knives are getting the same flow, the temperature should be the same for every sensor. If the flow or pressure varies slightly this can cause a significant difference in temperature. This causes the system to be sensitive enough to measure a small change in temperature when the only difference is 1-2 feet of hose length.