INTERSEEDING METHOD

Cover crop seeding is a popular and effective way to increase soil health, suppress weed growth, reduce soil erosion, reduce fertilizer costs and protect water supplies. Maximizing these benefits requires choosing the right method of cover crop seeding and the right equipment for the job.

Hiniker has the right cover crop seeding equipment systems for both broadcast and interseeding applications.

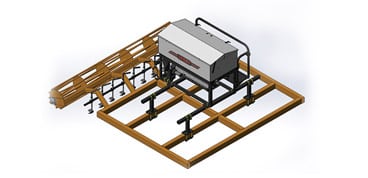

Growers with shorter growing seasons, in cooler climates, may choose the “interseeding” method. Hiniker offers 3-point-mounted, folding toolbars up to 40 feet in length (16 row 30 inches or 24 row 20 inches), along with toolbar-to-hopper mounting packages. These interseeding configurations allow for the precise placement of cover crops into standing corn crops in spring or early summer.

The Hiniker double disc openers feature 16-inch diameter discs, 12-inch diameter press wheels and easy adjustment of both seed depth and down pressure settings. Row units feature a generous 30 inches of under frame crop clearance and can be mounted in spacing as narrow as 7.5 inches. Row units can be mounted to existing toolbars from 4- through 7-inch sizes.

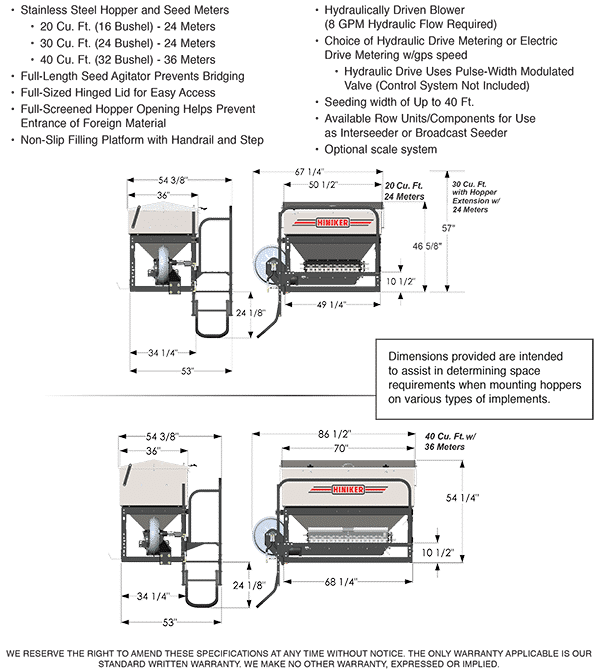

DURABLE & RELIABLE STAINLESS STEEL HOPPERS & METERING SYSTEMS

Hiniker offers two different hopper sizes and multiple machine configurations for traditional broadcast seeding as well as exclusive Hiniker interseeding options. These cover crop seeding systems are designed to fit different applications in different geographical areas. Available in 30- and 55-cu. ft. sizes, hoppers and metering systems are constructed of corrosion resistant #201 and #304 stainless steel for maximum durability and reliability.

30-cu. ft. hoppers are equipped with 24 seed meters, while 55-cu. ft. sizes have 36 meters. Metering systems are available with variable rate hydraulic drive or 12 volt variable rate electric drive.

Calibration Hopper

Hand held, hand operated hopper/metering assembly. Quick and easy way to provide calibration information required to program metering controllers. Includes both black and gray metering wheels to cover most popular seed types.

BROADCAST

(SOLID-SEEDING) METHOD

For traditional broadcast or solid-seeding applications. One-inch seed deflectors with universal mounting hardware can adapt to many types of implements and are capable of full coverage on 12- to 30-inch spacing.