Why More Farmers Are Upgrading to a Flail Forage Harvester This Season–If you’ve been relying on the same silage setup for the last decade, it might be time to take a closer look at a flail forage harvester. Because let’s be honest—old choppers and worn-out harvesters can only be patched together so long before they start holding you back.

The right flail system doesn’t just improve your harvest—it transforms it. From cleaner cuts to less downtime and better feed consistency, the upgrade can change how your entire season plays out.

Here’s why more growers are making the switch—and what makes a flail forage harvester a smart investment in real-world conditions.

It’s Built for Today’s Forage

Modern crops are tougher, higher-yielding, and more moisture-sensitive than ever. A traditional forage chopper just can’t keep up the way it used to.

A good flail forage harvester handles that extra load with ease. It powers through thicker stands, denser plant mass, and variable field conditions—without plugging or compromising chop quality.

You get consistent particle size, better compaction in the bunker, and cleaner feed for your livestock. That’s not just nice to have—it’s a real competitive edge.

Engineered for Uptime, Not Excuses

Harvest windows are tight, and weather never seems to cooperate. The last thing you need is a machine that breaks down just when the crop hits peak maturity.

Our flail forage harvester is designed to keep running—day after day, acre after acre. With a simplified driveline, easy-access grease points, and rugged frame construction, you can spend more time harvesting and less time wrenching.

Even better? Replacement parts are easy to find and fast to install. So if something does need attention, it’s a quick fix—not a full day lost.

Designed by Manufacturers Who Listen

Not all manufacturers are created equal. Our flail forage harvester manufacturers don’t just build equipment—they build relationships with growers.

We’ve spent years taking feedback from farmers in every corner of the country, and it shows. From smart rotor positioning to improved shielding and more intuitive controls, every detail has been fine-tuned to work better in the real world.

If you’re tired of equipment that feels like it was made in a vacuum, you’ll feel the difference the first time you fire it up.

Dealers That Know Their Stuff

When you’re dropping serious money on equipment, you want to know the people behind it actually have your back. Our flail forage harvester dealers aren’t just sales reps—they’re field-tested problem solvers.

They’ll help you match the right machine to your acreage, crop mix, and tractor specs. And they’ll stick with you after the sale to answer questions, make adjustments, or help with parts.

We hear time and again that support makes all the difference—especially when things get busy.

See It Work Before You Buy

Still on the fence? Check out our flail forage harvester videos and see the machine in action.

These aren’t flashy commercials—they’re real footage from real fields. You’ll get a look at machine performance, crop handling, chop quality, and operator features that matter.

A few minutes of video can give you more confidence than any brochure ever could.

It’s the Next Step Forward

You’ve already made smart decisions to get where you are today. Upgrading to a flail forage harvester is the next one.

Compared to an outdated forage harvester or an aging chopper that struggles under pressure, the difference in performance is night and day. Less plugging. Better feed. Easier operation. And the kind of uptime that helps you finish faster—even in tight conditions.

Built for Versatility Across Crop Types

Whether you’re working with haylage, green chop, or even high-moisture corn, a flail forage harvester gives you the flexibility to move quickly between crops without making major changes to your setup. That’s a huge plus when the window between harvest stages is tight and you need equipment that adapts as fast as your schedule does.

We’ve seen growers use the same machine on multiple fields and crops with great results. The ability to chop consistently across different moisture levels and densities means less stress and more confidence in what’s going in the bunker.

Better Output = Better Livestock Performance

At the end of the day, it’s not just about what’s coming out of the field—it’s about what’s going into your herd. A consistent, fine chop from a flail forage harvester leads to better feed conversion, improved digestibility, and a boost in animal performance.

Whether you’re running a dairy or beef operation, that kind of outcome affects everything from weight gain to milk production. And that’s exactly why more operators are upgrading from older forage harvester models that just can’t keep up with modern expectations.

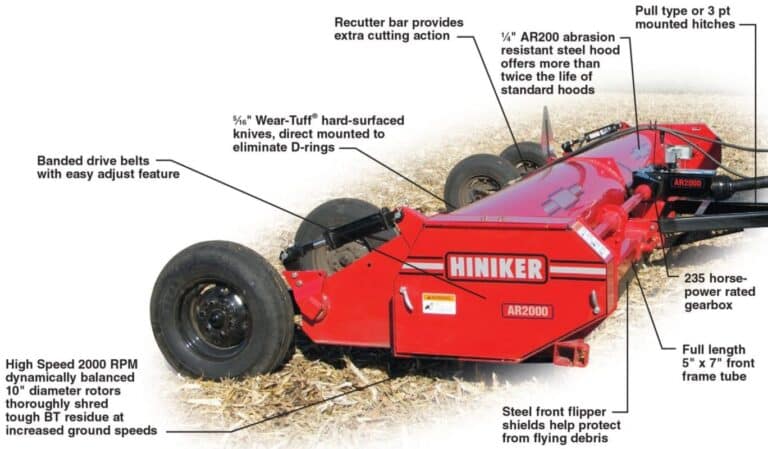

Every successful farming operation relies on hard work, the right people, and the proper equipment – that’s where Hiniker comes in. When you need the latest equipment to make your farm operations as efficient as possible, our team is ready to assist.

Hiniker is proud to be one of the most reliable sources when it comes to farm equipment manufacturing. Since 1970, we have been building durable and productive equipment to help our friends in the agriculture community.

We carry the latest equipment, whether it’s cultivators, cover crop seeders, rate controllers, shredders, windrowers, or a stalk cutter. Let Hiniker assist you with all your farming equipment needs.

Find your Hiniker Dealer today to find out more about our amazing agricultural equipment.

You can also follow us on Facebook for the latest news and updates.