Managing crop residue after harvest is critical. Particularly when protecting soil. Also, for preparing fields for the next season.

A properly used stalk cutter helps break down residue efficiently. It also supports better soil conditions over time. When residue is sized and distributed correctly, fields are easier to manage. When this happens, the fields often become more productive each year.

Why Post-Harvest Residue Management Matters

Crop residue affects soil temperature and moisture retention. It can also impact spring planting conditions. If residue is left unmanaged, it can slow soil warming. This can interfere with planting equipment and create pest pressure. Effective residue management helps fields recover faster. It also sets the stage for healthier crops.

With more than five decades of experience in agricultural equipment manufacturing, we understand how post-harvest decisions impact long-term soil performance. The right tools help farmers protect both their soil and their yield potential.

Understanding How a Stalk Cutter Improves Soil Conditions

A stalk cutter is designed to cut and size crop residue after harvest. This allows it to break down more evenly across the field. Smaller residue pieces decompose faster. This returns organic matter to the soil and improves nutrient cycling. This process supports better soil structure. It also reduces compaction over time.

Many operations pair cutting tools with a stalk chopper when they need additional residue sizing. Together, these tools help manage tough stalks while maintaining consistent residue distribution.

How Stalk Cutters Support Residue Breakdown

Residue that is cut into uniform pieces decomposes more efficiently. Even breakdown reduces the risk of residue clumps that can interfere with planting or restrict moisture movement. A well-adjusted stalk cutter ensures residue is spread evenly rather than concentrated in rows or piles.

In some systems, farmers may also use a stalk shredder or stover chopper, depending on crop type and residue volume. Each tool plays a role in preparing the field for winter and spring conditions.

.

.

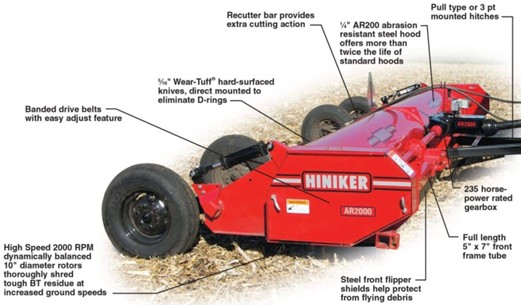

Our Approach to Building Reliable Residue Management Equipment

We design residue management tools with durability, consistency, and field performance in mind. Our equipment is built to handle tough post-harvest conditions while delivering reliable results across varying soil types. Strong components and stable designs help maintain performance during long operating hours.

Our experience building residue equipment allows us to support farmers who rely on tools such as stover shredder systems or a windrowing stalk shredder for specific field practices. Each design focuses on improving soil outcomes without adding unnecessary complexity.

Benefits of Using Stalk Cutters for Soil Health

Using a stalk cutter provides measurable benefits that extend beyond residue appearance. These advantages support both short-term field preparation and long-term soil productivity.

Key benefits include:

- Faster residue decomposition

- Improved soil moisture movement

- Reduced risk of planter interference

- Better soil temperature regulation

- Enhanced organic matter distribution

When residue is managed correctly, soil conditions remain more stable throughout the offseason.

Where Stalk Cutters Make the Biggest Impact

Stalk cutters are widely used in corn and row crop systems where heavy residue is common. These tools help reduce challenges associated with thick stalks and high-yield residue loads. Fields that receive consistent residue sizing are easier to manage during spring planting and early growth stages.

Some operations integrate cutting tools with a stalk chopper to achieve more aggressive residue processing when conditions require it. This flexibility allows farmers to adapt residue management strategies to their specific soils and crop rotations.

Why Choose Hiniker for Residue Management Equipment?

Hiniker has been building dependable agricultural equipment since 1970. Our focus on practical design and durability guides how we build residue management tools today. We understand that soil health depends on thoughtful post-harvest practices supported by reliable equipment.

Farmers trust our tools because they perform consistently in real-world field conditions. Our designs help protect soil structure while supporting efficient residue breakdown season after season.

FAQs About Stalk Cutters and Residue Management

How does residue sizing affect soil health?

Smaller residue pieces break down faster, improving organic matter distribution and nutrient cycling.

Do stalk cutters help with spring planting conditions?

Yes. Evenly sized residue reduces planter interference and improves seed placement.

Can stalk cutters be used in conservation systems?

Yes. Properly adjusted equipment supports residue management while protecting soil structure.

Effective residue management plays a key role in maintaining soil health and preparing fields for the next crop. A reliable stalk cutter helps break down residue evenly, improve soil conditions, and reduce challenges during planting. By supporting faster decomposition and better residue distribution, stalk cutting equipment contributes to healthier soils and more consistent field performance.

When it comes to premium farm equipment, Hiniker has you covered. Contact us today and let us help you get the right equipment for your specific needs.

.

.

We carry the latest equipment, whether it’s cultivators, cover crop seeders, rate controllers, shredders, windrowers, or a forage chopper. Let Hiniker assist you with all your farming equipment needs.

Find your Hiniker Dealer today to find out more about our amazing agricultural equipment.

You can also follow us on Facebook for the latest news and updates.