.

Keeping Windrowers Running Strong Season After Season

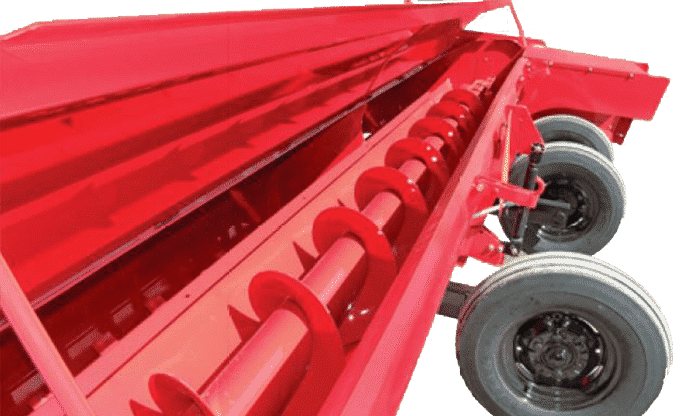

Growers who use windrowers to handle crop residue and forage preparation make equipment maintenance an essential component of their daily farm operations. When windrowers receive proper maintenance, they deliver consistent performance in the field and help reduce downtime while safeguarding your financial investment. Hiniker stands as a national leader in rugged American-made farm equipment and comprehends the operational demands placed on windrowers in various field conditions. Their design philosophy focuses equally on performance and serviceability.

Regular maintenance from blade inspection to gearbox upkeep enables operators to save both time and money during the entire season. These maintenance strategies enable your equipment to function optimally during both corn harvest preparation and hay laying for baling.

Inspecting Blades and Cutting Components

Windrowers depend on their blades to function properly. When you work with residue management or forage preparation dull or damaged blades lead to poor cutting efficiency resulting in uneven windrows. Regular visual checks before operation and after use remain essential. Check for cracks, bends, and uneven wear. When you replace blades in matched sets you maintain your machine’s balance and prevent vibrations that accelerate wear on additional machine parts.

Operating a windrowing shredder requires even stricter monitoring of blade sharpness. Cutting thick stalks or wet material at high speeds requires knives that remain both sharp and properly secured. The advantage of sharp blades comes from their ability to cut more efficiently and lower the machine’s workload while enhancing fuel consumption.

Prioritizing Drive System and Gearbox Maintenance

The gearbox and drive components of your windrower encounter significant stress during every movement through the field. Maintaining proper internal lubrication through routine oil checks and fluid changes prevents engine overheating. During operation, listen for abnormal noises including grinding and whining because they might suggest gear wear or incorrect tensioning.

Hiniker windrowers deliver high-capacity operation while featuring gearboxes that ensure sustained reliability. Despite their high build quality, all systems require regular maintenance to function properly. Maintaining long-term performance requires following the manufacturer’s service guidelines for greasing, torque checks, and oil changes.

.

Monitoring the PTO and Belt Tension

The transfer of power requires careful monitoring as a crucial operational focus. Efficient power transmission requires the PTO shaft and drive belts to maintain proper alignment and tension. Loose connections and belt slippage lead to uneven windrows and decreased cutting speed while accelerating bearing wear.

Belt tension typically varies during transitions from light to heavy crop conditions. The drive system needs a thorough inspection during the initial hours of use in new conditions to check if components remain tight and properly aligned.

Farmers who operate flail windrowers must perform tension checks with increased frequency. Material density along with field contour variations causes changes in the load experienced by these machines. Maintaining correct tension allows machines to operate uniformly across all working situations.

Cleaning and Post-Use Storage

Farmers commonly leave machines parked and walk away after completing a long day of field work. Regular removal of debris and buildup after use helps prevent corrosion and lowers the risk of damage from rodents and pests. Start by cleaning the deck underside and then brush the belts before checking the shields and safety covers. These minor actions help protect the machine from premature wear and tear.

Keep windrowers dry and covered during storage throughout the off-season whenever you can. Limiting elemental exposure while storing equipment decreases the frequency of repairs during the off-season. Stored equipment remains functional longer when operators drain fluids and relieve belt tension and support the frame structure.

Working With the Right Equipment Partner

The foundation of proper maintenance requires the selection of both a suitable machine and a reliable support network. Hiniker built its strong reputation for reliable flail windrowers through machines that withstand real-world conditions and maintain ease of servicing. Their equipment design focuses on accessibility which allows routine maintenance tasks to be completed without extensive downtime or the need for specialty tools.

You gain additional value by working with an experienced flail windrower dealer. Your dealer helps you maximize your machine’s performance annually through the supply of spare parts as well as setup advice and seasonal service. Hiniker dealers provide essential support for troubleshooting and upcoming harvest preparation to ensure your maintenance success.

The Role of Maintenance in Field Performance

Windrowers that receive regular maintenance operate more effectively in the field over their extended lifespan. Windrows that are clean and uniform enhance drying efficiency while improving baling performance and field appearance. These machines encourage improved crop regrowth for forage and make cleaning up fields after harvesting corn or small grains easier.

A well-maintained machine partnered with shredders & windrowers produces efficient, secure and uniform field passes. This brief time investment yields fuel savings and wear reduction while providing peace of mind throughout peak operational periods.

Contact Your Local Hiniker Dealer Today!

Hiniker windrowers combine durable construction with outstanding performance to match your work ethic. Reliable support combined with routine maintenance keeps machines in optimal working condition.

Reach out to your local Hiniker Dealer today to receive professional advice about replacement parts or to explore new flail windrower technology and residue management solutions.

.

.

Every successful farming operation relies on hard work, the right people, and the proper equipment – that’s where Hiniker comes in. When you need the latest equipment to make your farm operations as efficient as possible, our team is ready to assist.

Hiniker is proud to be one of the most reliable sources when you need a windrower manufacturer. Since 1970, we have been building durable and productive equipment to help our friends in the agriculture community.

We carry the latest equipment, whether it’s cultivators, cover crop seeders, rate controllers, shredders, windrowers, or a forage chopper. Let Hiniker assist you with all your farming equipment needs.

Find your Hiniker Dealer today to find out more about our amazing agricultural equipment.

Follow us on Facebook